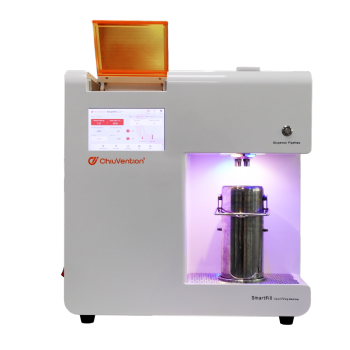

Martindale Abrasion & Pilling Tester-Digitally-Driven Type

Smartindale Martindale Abrasion and Pilling Tester is used for fabric abrasion and pilling tests. It generates a Lissajous curve with a digital algorithm, and then drives the friction, achieving accurate running without calibration. You can switch test modes such as the abrasion test to the pilling test with one click without changing the pins. You can also control and monitor the Smartindale from your smartphone by SmarTexLab app connection and the test data can be uploaded to ERP or LIMS system, to realize smart testing.

It can test the abrasion and pilling resistance of cotton, linen, silk woven fabrics and other textiles, film materials, knitted fabrics, woolen fabrics, artificial leather, synthetic leather, gloves, labor protection materials, and so on. It is widely applicable to more than 20 international standards such as ISO 12945-2-2020, ISO12947-2-2016, BS EN 530-2010; ASTM D4970/4970M-22, etc.

Smart instrument

This Smartindale Martindale Abrasion & Pilling Tester can be connected through Wi-Fi with SmarTexLab App installed in the smart phones, then you can set parameters, monitor the test status, and receive equipment warning reminders, replenishment reminders, etc., and share the Martindale Abrasion & Pilling test results with one click.

Calibration-free

The dual action of servo driver and position sensor allows the Smartindale Martindale Abrasion & Pilling Tester to achieve accurate testing continuously.

The original digital drive achieves a higher level of test accuracy.

Smartindale Martindale Abrasion & Pilling Tester replaces the traditional analog drive with a digital drive, it is an exclusive innovation in the industry with the combination of dual servo motors, micro controller, embedded, mathematical model, point-to-point drive, etc., and it can directly generated LISSAJOUS by single point, with higher precision and reliability of the Martindale Tester.

One-click to shift the testing modes

Compared to conventional Martindale abrasion tester, with the Smartindale, you don’t need to remove the top plate and change the pins, just click one key of the screen to switch the testing modes from abrasion to pilling (e.g. Abrasion, Pilling, Line).

Ergonomic design

The moving guide plate of this Martindale test machine can be operated by one hand and automatically close, with anti-collision function, more friendly to testers.

Reliable martindale test

The excellent manufacturing accuracy of machining and assembly makes the abrading table and specimen holder are highly parallel to each other during running, and the specimen holder has a small run out to the surface of the abrading table (less than 0.05mm), which is more conducive to obtaining reliable Martindale test results.

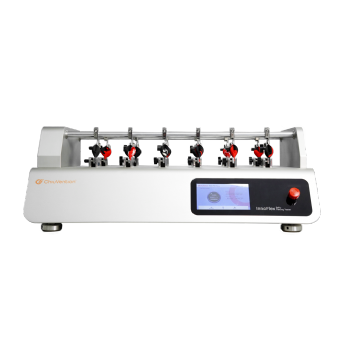

Accessories of Martindale Abrasion and Pilling Tester

Accessories

Fuse tube 2pcs

Foam wool 9 pcs Φ38 mm

Wool felt 18 pcs Φ90 mm,Φ140 mm

Wool abrasive 9 pcs Φ140 mm

Sampling plate 3 pcs Φ38 mm,Φ90 mm,Φ140 mm

Sampler 1 pc for pilling test

Sampler 1 pc for abrasion test

Press 1 pc Φ126mm,2.5kg

Fixture1 9 sets for pilling test

Fixture 2 9 sets for abrasion test

Weight 1 9 sets 12Kpa

Weight 2 9 sets 9Kpa

Rubber ring 9 pcs

Test pen 1pc

Connection shaft 9pcs for pilling test

Connection shaft 9pcs for abrasion test

Stainless steel ring 9pcs 260g