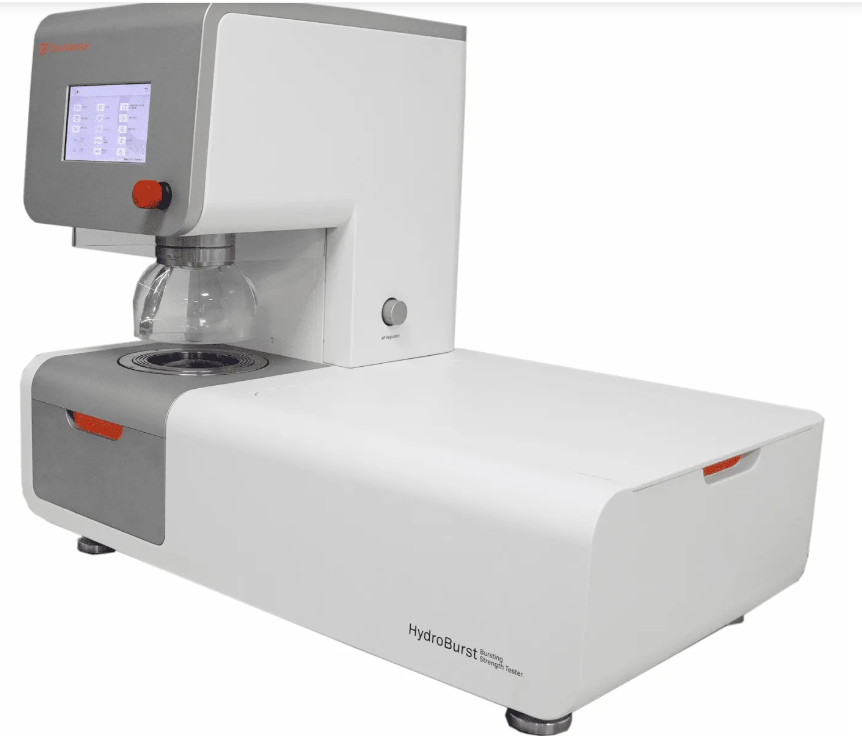

The HydroBurst Automatic Bursting Strength Tester

The HydroBurst Automatic Bursting Strength Tester utilizes hydraulic bursting (diaphragm method) to determine the bursting strength and expansion of knitted fabric, woven fabric, non-woven fabric, laminated fabric, elastic woven fabric, paper and other materials when subjected to stress in both warp and weft

directions, as well as in all other directions, to get the material's resistance to bursting.

The Features of HydroBurst

Smart instrument with IOT function CV142 can be connected to mobile phone, enabling users to set parameters, operate and monitor testing status remotely, and directly obtain testing results and share them with one click.

Smooth operation, precise and durable

The hydraulic system adopts full servo control and precise screw drive, providing smooth operation, precise and durable transmission, and low noise.

High-precision testing with low error

The pressure measurement part uses a high-precision pressure sensor, with accuracy up to 0.2 level (that is, the error is 0.2% of

the maximum range).

Longer service life of sensors

CV142 is equipped with the Panasonic laser displacement sensors which have no rod and are easy to replace testing cups, thus providing sensors with better protection and reducing the risk of damage compared to traditional rod-type sensors.

Automatic testing improves efficiency.

During the testing process, the protective cover automatically descends, and then the testing cup is pressed for testing.When the

test is completed, the testing cup automatically lifts, and the protective cover automatically ascends. The testing process is automated, without manual operation, which improves work efficiency and reduces operation risks.

Smart identification system for testing cups

When changing the testing cup, the system can automatically identify the current testing cup model and switch the testing parameters automatically, which also greatly improves work efficiency.

In addition, the mechanical shell of HydroBurst is made of steel plate electrostatic spraying technology, which makes the appearance generous. The mechanical interior is mainly composed of high-quality lightweight all-aluminum structure,

which greatly reduces the weight of the whole machine.

Specification

Testing mode: constant speed bursting, constant pressure bursting, constant expansion bursting, and fixed-time

bursting.

Measurement range: 0-10 MPa ±1%.

Testing rate: 50-500 ml/min.

Hydraulic medium: glycerin.

Power 110V~220V 50~60Hz

Weight 150kg

Dimensions

500mm X 830mm X 660mm(W*D*H)

Testing cup size:

7.310 cm² (diameter: 30.5 mm ±0.2 mm),

10 cm² (diameter: 35.7 mm ±0.2 mm),

50 cm² (diameter: 79.8 mm ±0.2 mm),

100 cm² (diameter: 112.8 mm ±0.2 mm).

Maximum expansion height: 70 mm ±1 mm.

Operating environment: temperature: 20°C ±5°C, humidity:

50~70%.

Installation conditions: air supply pressure of 6~8 bar

(ensure that the air is clean and dry).

Standard

GB∕T 7742.1-2005 、 ISO13938-1-2019 、 ASTMD3786 、 ISO

3303-2-2020